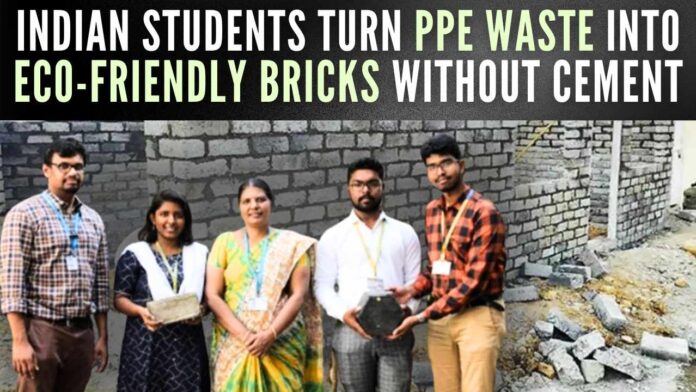

Sona College students make poly bricks out of PPE waste

A team from the civil engineering department of Sona College has devised a method to turn hospital personal protective equipment (PPE) waste, which typically swells up landfills, into bricks that are stronger and do not use any cement.

The team, Aravind Kumar from the final year, Kamalesh J B and Dharani Raj U, both from third year, and Adhavan P and Harshini E K from the second year — found this solution while participating in a nationwide competition.

The “poly bricks” have a three-time higher compressive strength as compared to the common red bricks and are also much lighter and can be produced in a far shorter time.

Since the curing time to reach ISO standards is less than 24 hours, the bricks are ready quicker and cheaper than common red or concrete hollow bricks and meet the water absorption specifications.

“The technology is now available to hospital chains and other organizations interested in technology transfer to help tackle PPE waste and reduce poisonous emissions,” Chocko Valliappa, Vice Chairman, Sona Group of education institutions said.

The poly brick-making process starts by sterilizing PPE kits with ultraviolet (UV) rays, subjecting them to heat at 160 degrees centigrade, adding sand aggregates, and casting the polypropylene mass into bricks.

The poly bricks are eco-friendly as they do not use any cement or water in the process and cause minimal in-process emissions as the PPE plastic waste is subjected to less than 200 degrees centigrade.

According to the educational institution, these eco-friendly bricks can be used as regular bricks for walls as also as paver blocks instead of red bricks — in the process reducing plastic waste as well as pollution caused during cement production. Poly bricks have good cement adhesion and can be plastered with cement.

Dr. N Karuppasamy, Assistant Professor of Civil Engineering, Sona College of Technology who mentored the team said that a patent application has been filed for this technology.

The civil engineering department has also patented a technology to use plastic waste in brick production that replaces almost 70 percent of sand with plastic.

The WHO recently said the use of PPE kits during the COVID-19 pandemic was putting on the environment, due to their single-use nature.

[With Inputs from IANS]

PGurus is now on Telegram. Click here to join our channel and stay updated with all the latest news and views

For all the latest updates, download PGurus App.

- CISF personnel to be deployed at ED offices amid growing security concerns - April 29, 2024

- Canada: Pro-Khalistan slogans raised during PM Justin Trudeau’s speech - April 29, 2024

- Indian Navy assists Panama-flagged crude oil tanker after it comes under Houthi’s missile attack; crew including 22 Indians safe - April 29, 2024

I am proud of their innovation. Hope this does not become one day news. Someone takes it forward