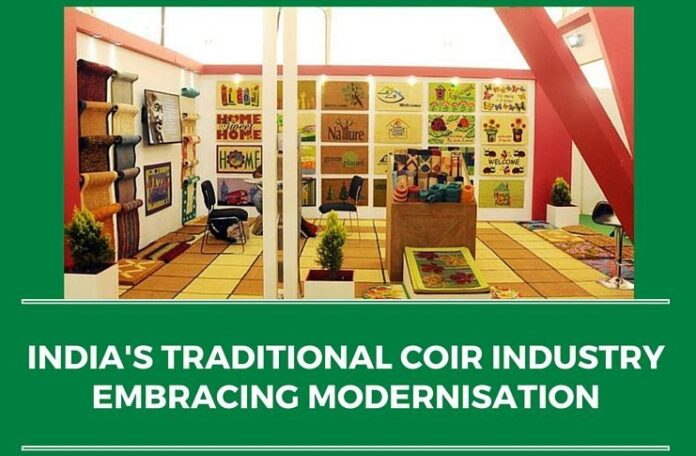

With the steady pace of modernization, workers groups appear to be at home in the city of Kerala’s Coir, where trade unions would often be accused of derailing industry.

[dropcap color=”#008040″ boxed=”yes” boxed_radius=”8px” class=”” id=””]I[/dropcap]t is one of the India’s oldest industries which is slowly started accepting modern equipment and the men who would be taking over who are the future of Coir Industry say there is no other way out.

Kerala’s Revenue and Coir Minister Adoor Prakash explains why.

“This is a traditional industry but the new generation is not taking to it, precisely because of the traditional methods used in the industry,” the minister told IANS in an interview.

“We have no option but to go for mechanization to rectify this situation.”

[dropcap color=”#008040″ boxed=”yes” boxed_radius=”8px” class=”” id=””]K[/dropcap]erala’s coir is considered one of the finest in the world, and its products enjoy global appreciation and demand. It employs some 3.5 lakh people in the organised and many more in the unorganised sector across the state.

For decades, producing fibre from coconut husks was a tedious process. The husks would be kept in water for six months, and they would emit a foul smell. Workers would finally get into this stench to extract the husks – and fibre.

For all this back-breaking work, the wages they got was a pittance – as little as 70 paise a day.

This is when Kerala decided to deploy machines to do a better job. Although the process began some time back, the pace has quickened in the past few years.

“At one time, the workers didn’t appreciate mechanization,” G.N. Nair, managing director of the state-run Kerala State Coir Corporation Ltd, told IANS at the venue of the sixth edition of Coir Kerala 2016 here.

“There was a lot of opposition to the introduction of machines. This was akin to the way computers were first received by people who feared they may lose their jobs,” Nair explained.

“But work now has become easy, more humane, more decent. Our machines are also used to twist and twist the fibre to make fine yarn.

[dropcap color=”#008040″ boxed=”yes” boxed_radius=”8px” class=”” id=””]P[/dropcap]“roductivity has shot up because of mechanization. Now, in an eight-hour shift, we produce 1,200 sq km of fibre per shift. When output is more, we can sell more. Income is more. Naturally, wages also go up.”

When Nair took charge of the Kerala State Coir Corporation Ltd in January 2012, it was earning Rs.57 crore. This had doubled to Rs.120 crore ($17.6 Million) in 2014-15, a period coinciding with growing mechanization.

To produce machines within the country for the industry, the Kerala State Coir Machine Manufacturing Co came up last year at Adoor, about 80 km from Alleppey. The earlier machines were imported.

[dropcap color=”#008040″ boxed=”yes” boxed_radius=”8px” class=”” id=””]M[/dropcap]inister Prakash said the Kerala government’s intention was to spread the mechanization process across the length and breadth of the state where coir making is the biggest cottage industry.

“We are helping all the cooperative societies to mechanize,” he said, adding that Kerala wanted to increase its share of coir production vis-a-vis two other states which too play a role in the industry: Tamil Nadu and Karnataka.

Nair warned that the traditional coir industry in Kerala “will die on its own” unless it took to mechanization. “The industry has to be mechanized. Tradition is good, but modernization is vital. The two must marry.”

Notes:

1. IANS

2. The conversion rate used in this article is 1 US Dollar = 68.18 Rupees

- Pentagon cancels aid to Pakistan over record on militants - September 2, 2018

- The curious case of Tamil Nadu’s opposition to NEET - September 4, 2017

- If 2.6 Billion People Go To War: India vs. China - July 22, 2017